Robotic arms, which are at the heart of modern production and manufacturing change the norms in a way that was previously not possible. They bring precision, safety and efficiency. These technological marvels, sometimes referred to as robot arms, have become indispensable in industries worldwide driven by the urgent necessity of reducing operating costs and maintain high standards of quality. Incorporating robotic arms into the production lines allows companies to not just cut costs, but also enhance the safety of workers and increase productivity. We’ll explore how these innovative robots are changing the face of industry.

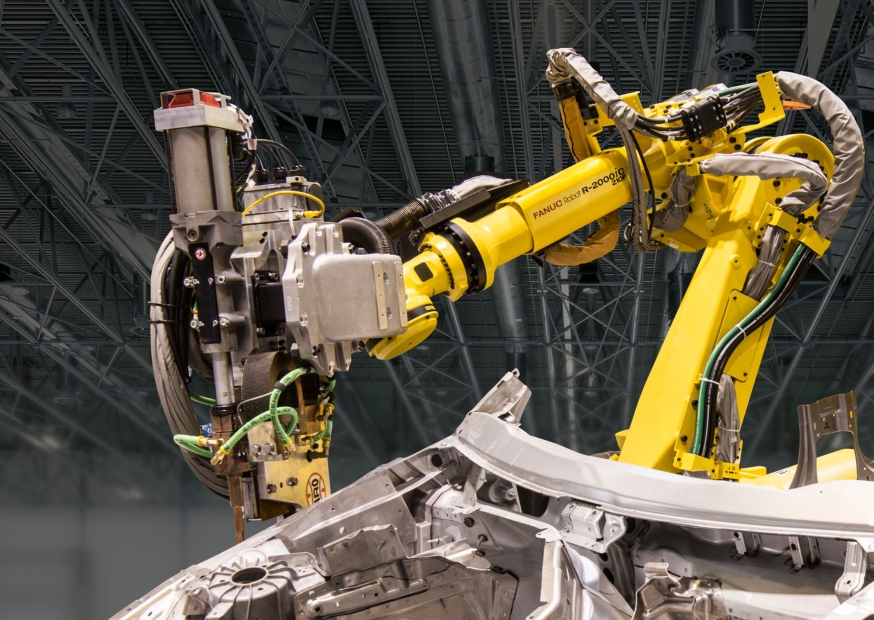

Image credit: automatedsolutions.com.au

The main reason for the increase in global robotic arm usage is cost efficiency. The increasing pressure on factories to reduce manufacturing errors, material waste and workplace accidents is constant. Robotic arms have been designed to combat these challenges. Robot arms are more accurate than humans when it comes to performing repetitive tasks, which means they can reduce costs and avoiding costly errors. Robotic arms are used in many industries that require large quantities of material such as the automotive industry, to guarantee perfect assembly. This accuracy results in substantial savings, as less defects means less time spent reworking, waste and work.

The safety of robot arms is also an essential element. Many manufacturing tasks like working with hazardous materials or employing heavy machinery can be dangerous to human workers. Utilizing robot arms, companies can remove employees from these dangerous environments, drastically cutting the possibility of injuries sustained in the workplace. A robotic arm, designed as a kinematic chain with moveable joints, is modeled after the functionality of a human arm, however it is free of the threat of physical harm. Equipped with programmable hand end effectors, these machines are able to perform tasks that are hazardous for humans, such as welding or spinning.

The versatility of robotic arms makes them a game-changer across diverse industries. Robot arms are adaptable to many different tasks. From automotive assembly, to electronics production. The fact that they can be programmed allows them to execute complex tasks, such as tending machines painting, painting, or fiberglass application with unparalleled quality and consistency. Robotic arms have revolutionized the process of palletizing in warehouses, automating it with speed and precision. The automation does not just boost efficiency but also ensures security, as robot arms are able to work for hours without fatigue.

Cobots are a new breed of robots able to work in conjunction with humans. Cobots, that are outfitted with a robotic arm, are able to be able to interact with humans in a seamless manner in contrast to industrial robots which are usually confined to cells. Cobots with robotic arms are able to perform routine or heavy lifting tasks in factories and allow human workers to concentrate on more difficult tasks. The collaboration improves productivity while ensuring a safe work surroundings, as cobots can be programmed to stop or alter their movements if a human is within the vicinity.

The significance of robotic arms extends beyond the safety and efficiency of robotic arms into the very foundation of modern manufacturing. They are essential to industries that require high precision for tasks like welding, assembly or material handling. For example, in automotive production, a robotic arm is able of rotating and repositioning parts while assembling, ensuring flawless alignment, without the intervention of humans. As in electronics, robot arms handle delicate components with care, minimising damages and improving the quality of output.

Robotic arms are expected to grow in importance as industries evolve. They are a cornerstone for the future of manufacturing due to their ability to lower costs, enhance security and adapt to various tasks. Through the combination of cutting-edge technology and human ingenuity robot arms aren’t just tools. They are partners in progress, driving innovation and altering the way we build the world around us.